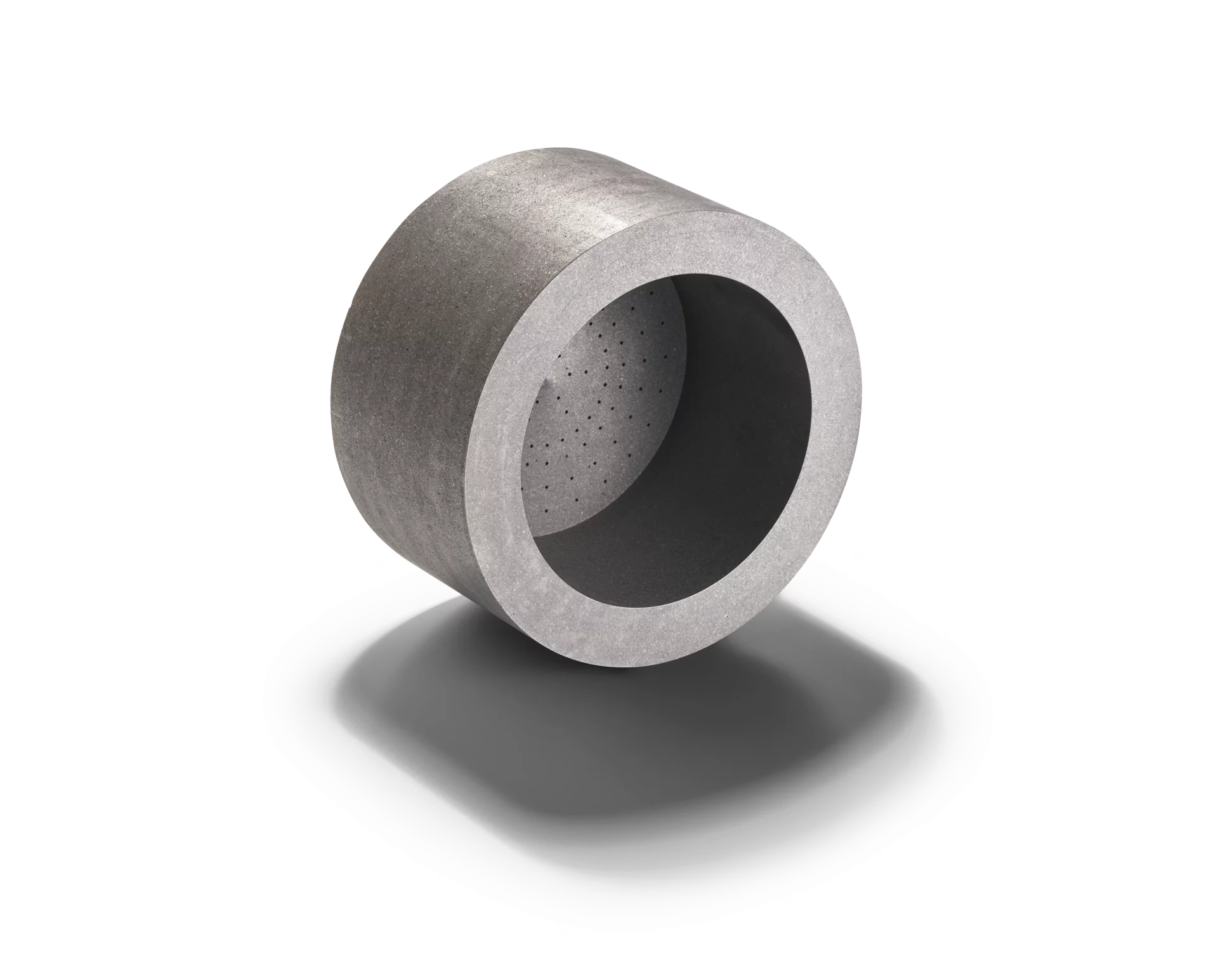

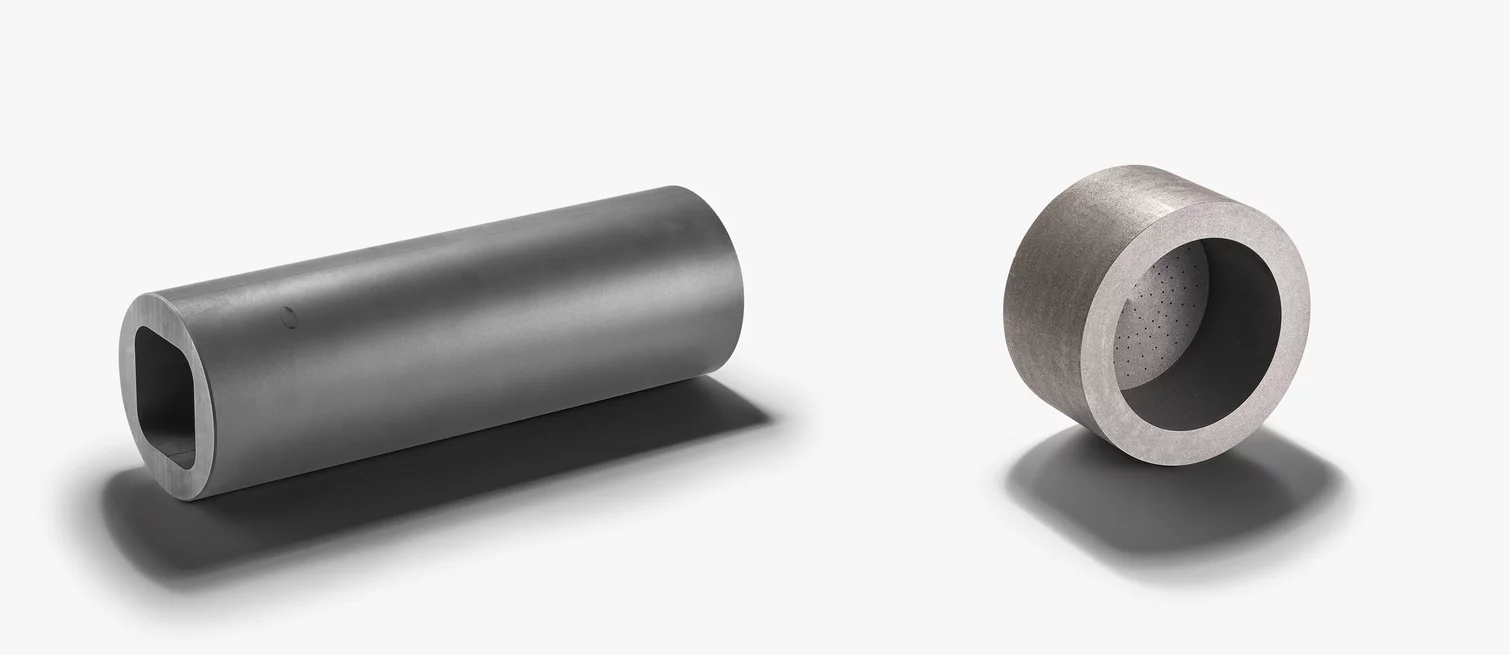

Ingot molds and crucibles for continuous casting

The use of graphite also pays off in continuous casting. Our casting dies for nonferrous metals and precious metals reliably resist attack by the melts and have no effect on the composition of the final product.

Reliable top quality for continuous casting

Graphite casting dies behave completely neutral

In continuous casting, the molten metal is continuously let into our graphite mold, where it solidifies and is withdrawn in an oscillating manner in the casting direction. In this way, for example, strips, wires, tubes and round or square bars can be produced quickly and in high quality. Graphite proves to be a superior material here, with no influence whatsoever on the composition of the final product. For example, the graphite die does not release any graphite particles into the melt, which means that there are no particle inclusions in the product that could cause problems in downstream work processes. Our graphite molds therefore enable continuous monitoring of metal processing from the liquid to the solid state.

Graphite components with consistently high-quality properties

Thanks to our many years of experience and great materials expertise, we can optimally design materials and their processing to suit the application required by the customer. We have access to a wide variety of materials and finishing techniques. All our solutions have outstanding material properties in common. For example, our casting dies are characterized by consistent thermal conductivity, chemical and thermal resistance, and high load-bearing capacity. Added to this are excellent thermal shock resistance, low thermal expansion and good lubricating and sliding properties, as the molten metal does not wet the graphite surface.

Innovative Solutions for Thermal Applications

Schunk Industry: Leading the Way in Glass Handling

Efficient EDM solutions with precise graphite electrodes

Downloads

Let us advise you

Do you have any questions about our products in the area of continuous casting?