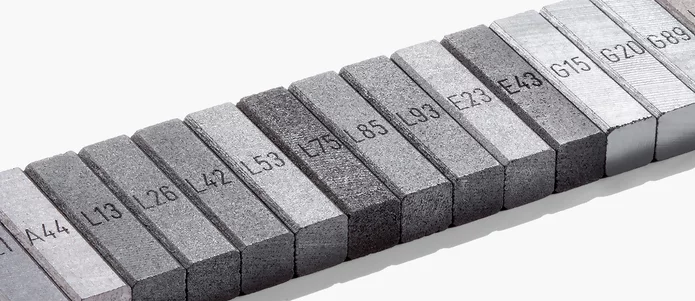

Carbon Brushes

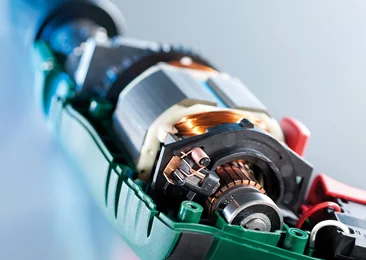

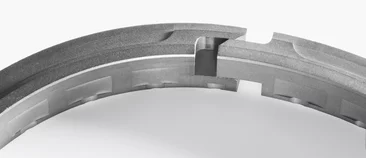

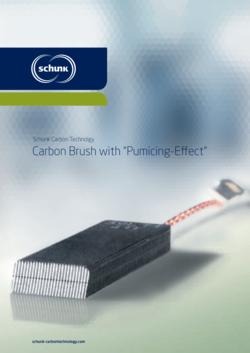

As a central element of power transmission in electric motors, our carbon brushes ensure reliable performance and minimal downtime. Depending on the application, we supply customized geometries, material mixes, and additional functions—from quick start and radio interference suppression to shut-off and signaling functions.