Innovative Solutions for Thermal Applications

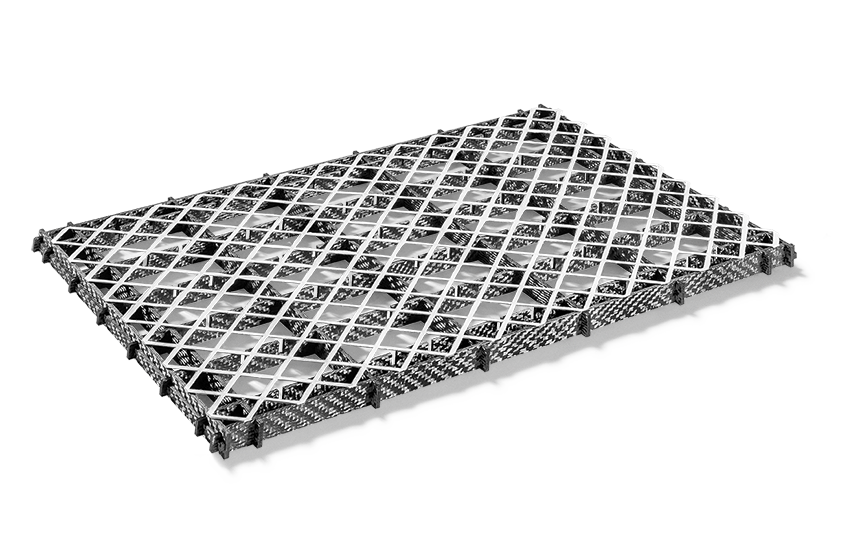

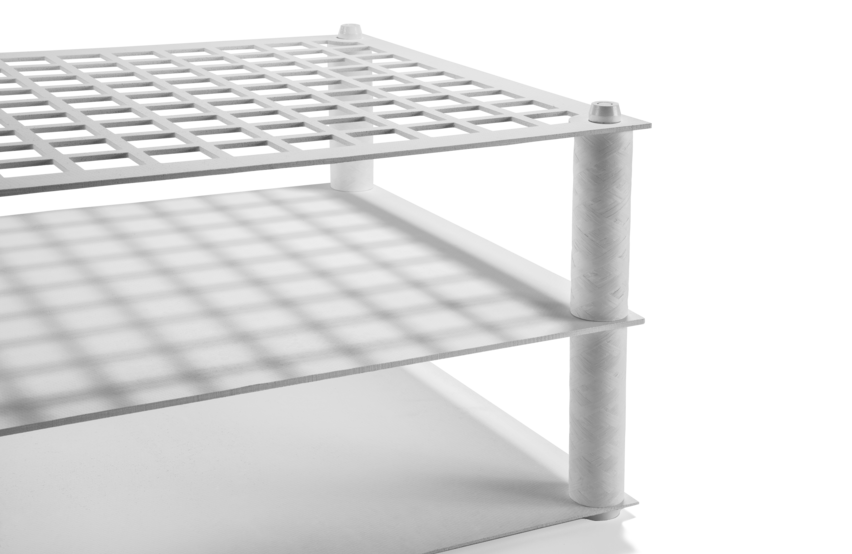

Durafox® Ceramics – All-oxide Fixture

We also offer our individual fixtures for oxidizing and corrosive atmospheres. For this purpose, we use a fiber composite material made of ceramic fiber and ceramic matrix, which remains resistant to temperature changes and distortion in high-temperature applications. Compared to steel or monolithic ceramic, slimmer designs can be achieved, resulting in significant energy cost savings. We can also design our Durafox® fixtures to fit your furnace, application and product exactly. Here for, we provide expert support in consulting, design and manufacturing.

Take advantage of these benefits:

- Oxidation and corrosion resistance

- Resistance to temperature changes up to thermal shock

- Ductile fracture behavior

- Distortion-free under thermocyclic load leads to less scrap

- Low heat capacity leads to optimized production times

- Ideal for automated loading of batch fixtures

Heat treatment with high-level know-how

New solutions for your applications

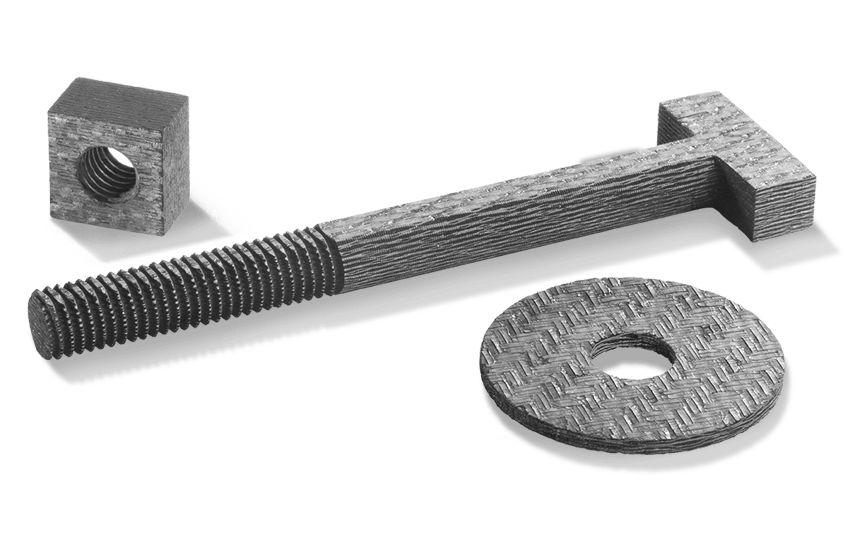

Standard parts list in the field of high temperature applications

The solution for oil quenching