Innovative Solutions for Thermal Applications

Graphite Electrodes for EDM

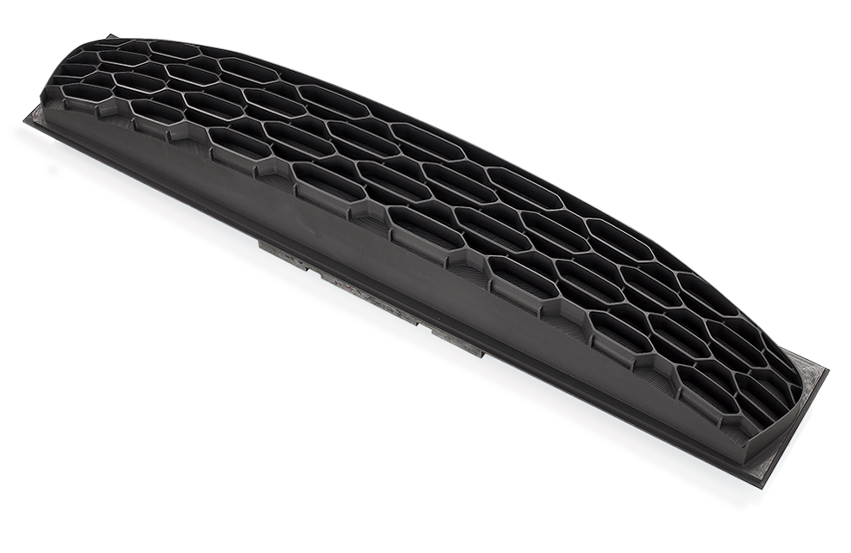

With graphite electrodes, geometries can be achieved using spark erosion that would be difficult and expensive or outright impossible with ordinary milling techniques. Graphite electrodes also offer numerous advantages with respect to time and material when compared to copper electrodes. The important thing when it comes to the production of the delicate graphite electrodes is the manufacturing and material know-how. Schunk combines the two: hence, only high-quality, customer and application specific graphite grades are used which have a long and successful track record in the EDM industry. Our highly-qualified team analyzes the 2D or 3D CAD design of the workpiece or the casting mold sent in by the customer and then suggests an appropriate graphite material based on the results. If the customer accepts our offer, we begin with the high-precision production, for which we can use every kind of rapid clamping system, such as Erowa, 3R or Hirschmann.

You benefit from these advantages:

- Highly-specialized team with profound material and production know-how.

- Wide range of customized and application-specific graphite materials

- Comprehensive service, from initial analysis to shipping – fast and efficient

- Dust-free production facility through outsourcing of machining work

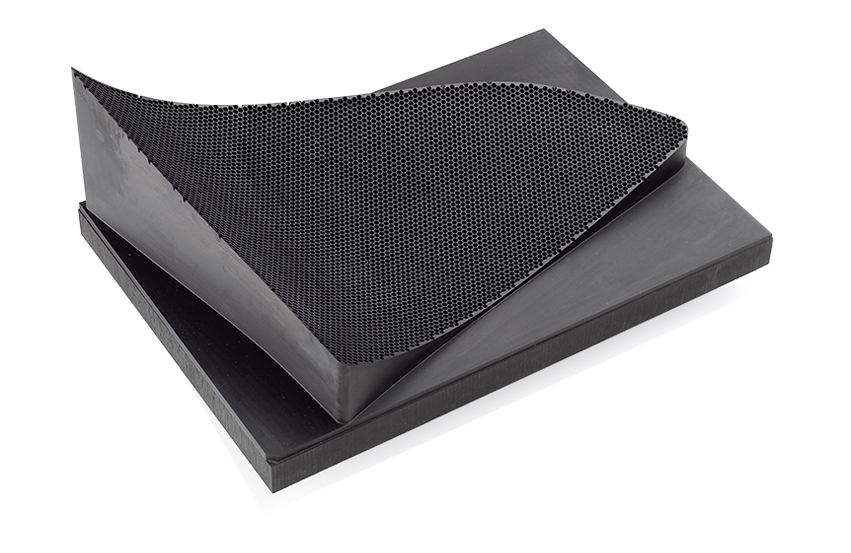

Heat treatment with high-level know-how

New solutions for your applications

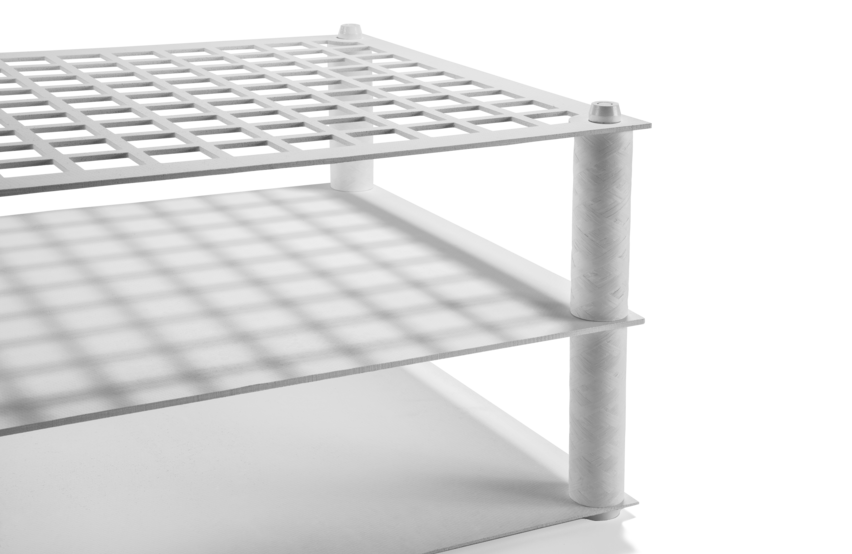

The solution for oil quenching

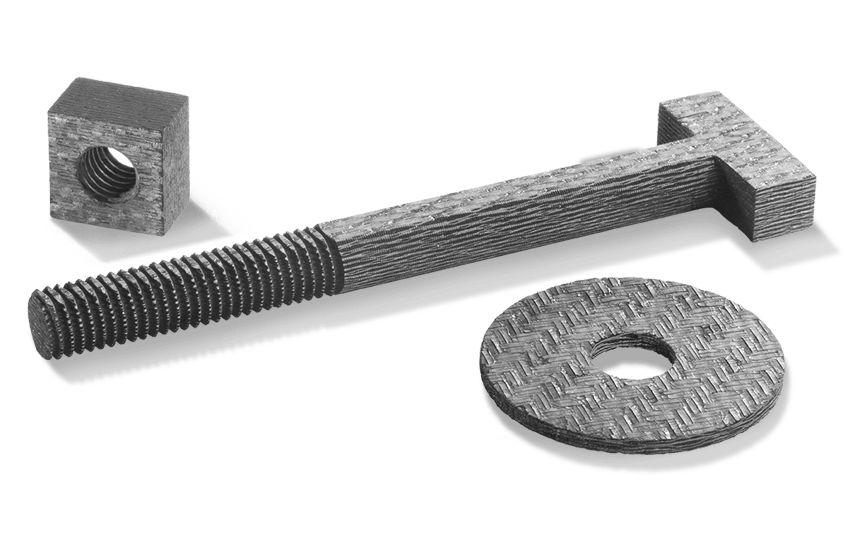

Standard parts list in the field of high temperature applications

Schunk Industry: Leading the Way in Glass Handling