Innovative Solutions for Thermal Applications

Components and Decoating Service for CVD Coating

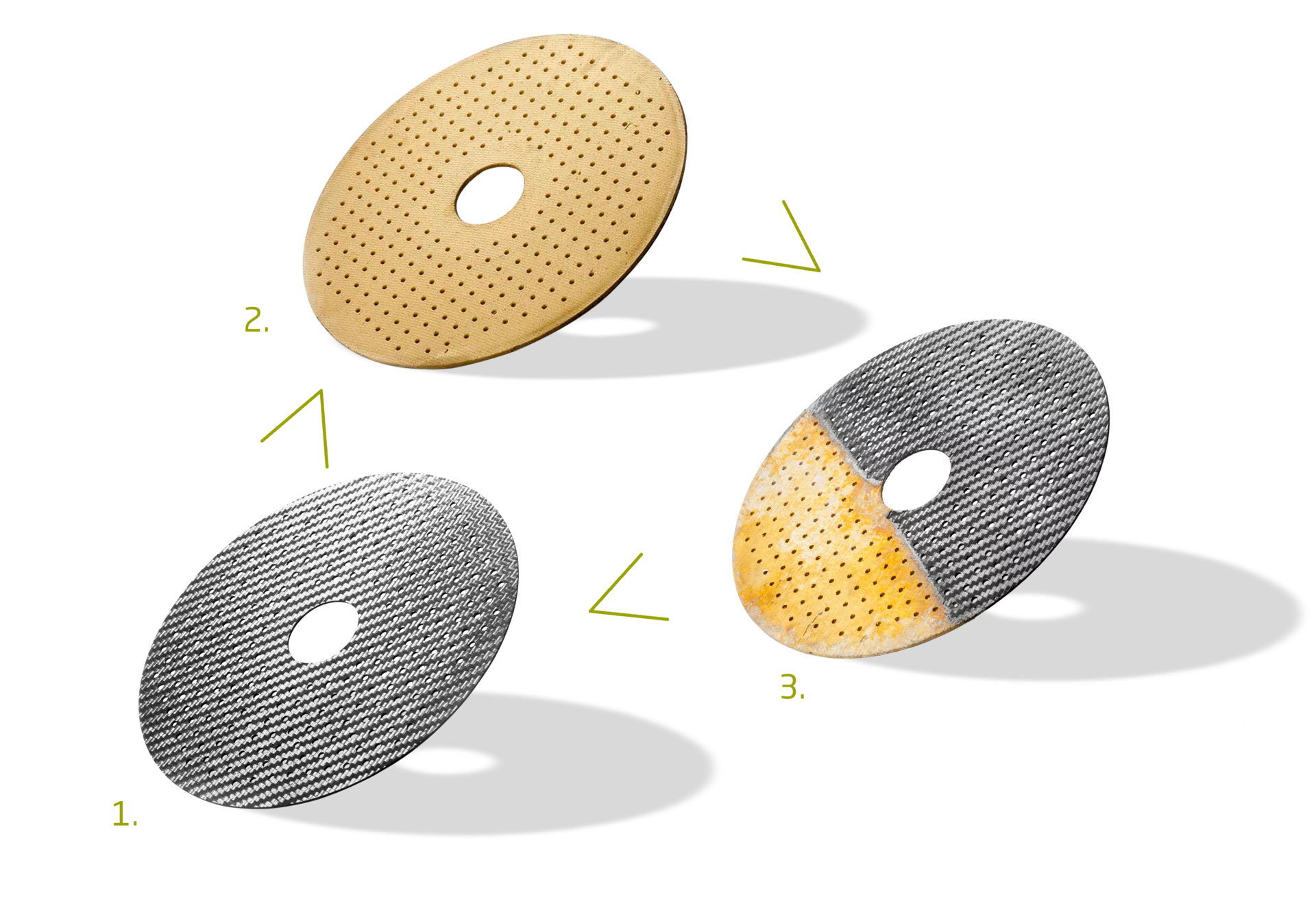

For the CVD process, Schunk supplies all components for gas guidance as well as for charging. We manufacture all components from graphite or CFRC materials. They have proven themselves in the application and are ideally suited to the challenges of CVD coating. For any desired dimension, from simple to highly complex designs, we ensure consistently high quality. For charging plates, the use of CFRC offers particular advantages because of the positive material properties and the possible decoating. With professional decoating, we have developed a resource-saving and economical method to reprocess and reuse CFC charging plates.

Take advantage of these benefits:

- Proven material for insulations

- High quality in all sizes and designs

- CFRC has no brittle fracture behavior, therefore no batch loss

- Increased productivity per production batch

- Longer service life

- Decoating service removes CVD layers and enables reuse of CFC charging plates

Heat treatment with high-level know-how

New solutions for your applications

Standard parts list in the field of high temperature applications

The solution for oil quenching