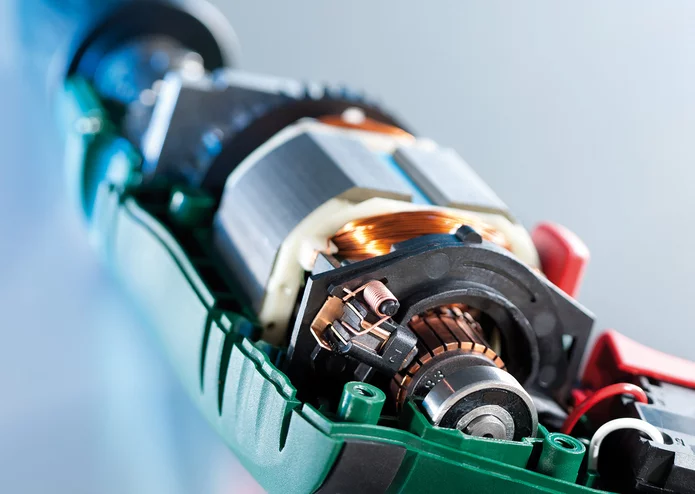

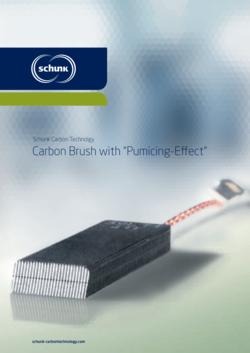

Electric Motors – Tailored Solutions for All Requirements

Carbon brushes in electric motors must meet various specific requirements depending on the field of use – from high speeds to changing loads and extreme environments. Key is the precise matching of material, geometry, and impregnation to the conditions to ensure efficiency, service life, and operational safety in industrial, household, or niche markets.