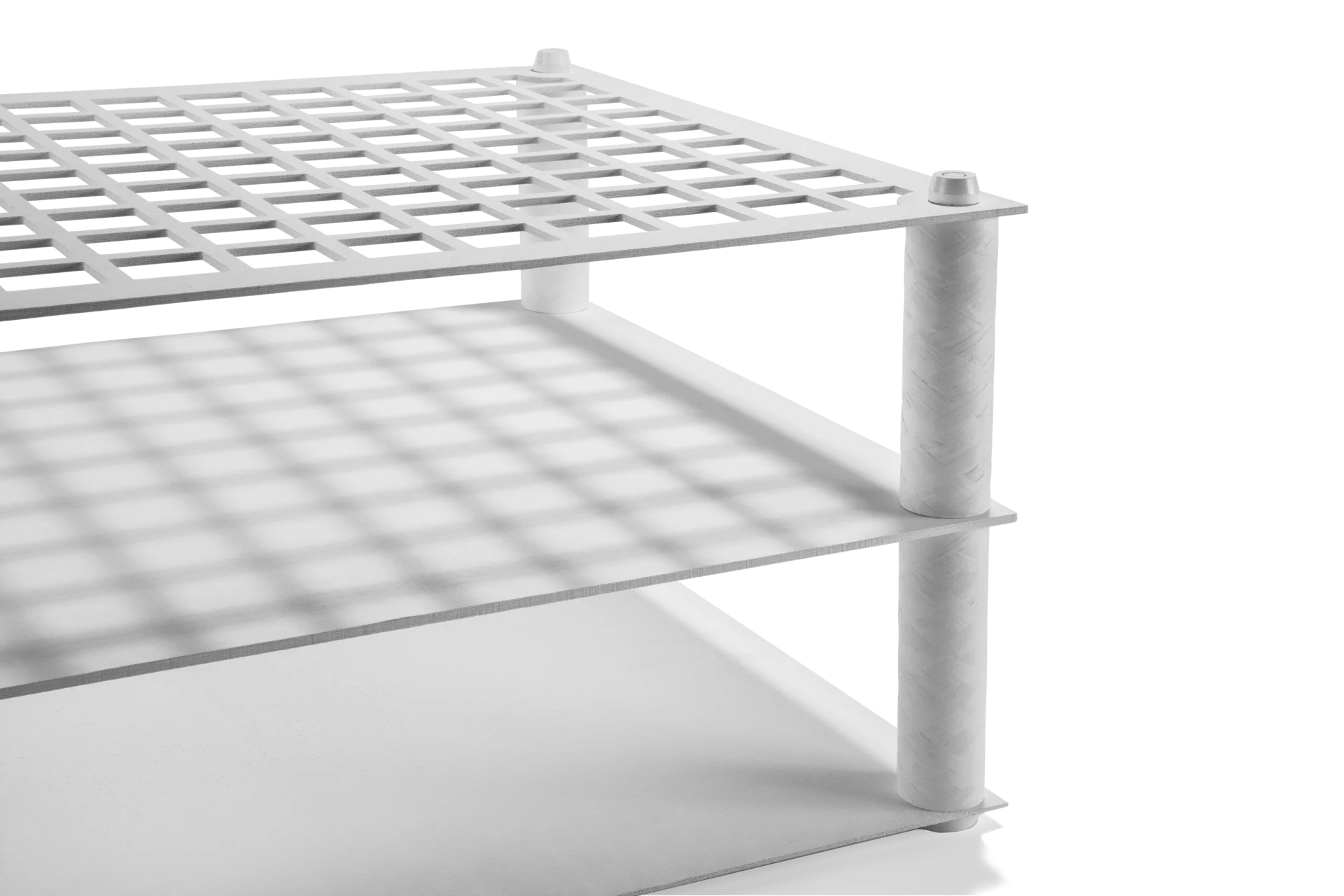

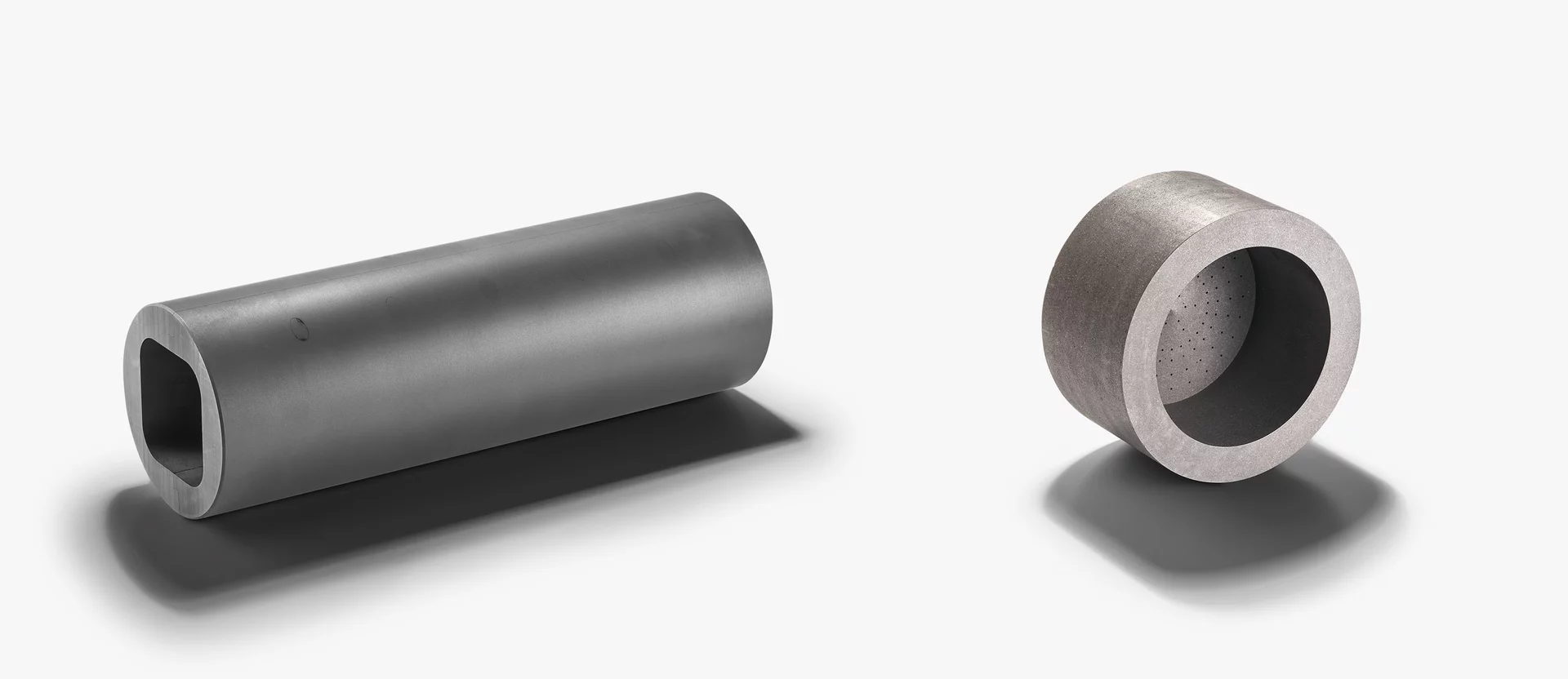

Advantages of CFC fixture systems

-

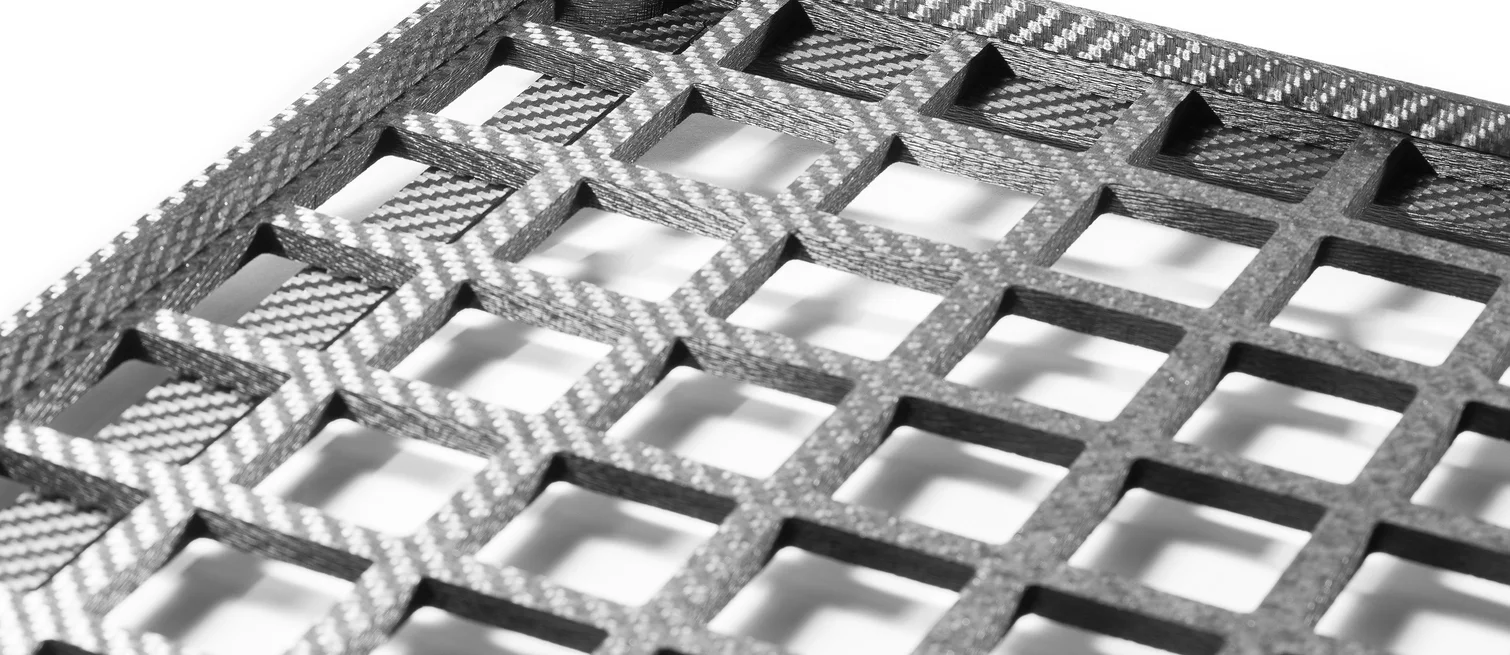

High strength and distortion-free even under frequent thermal cycling

-

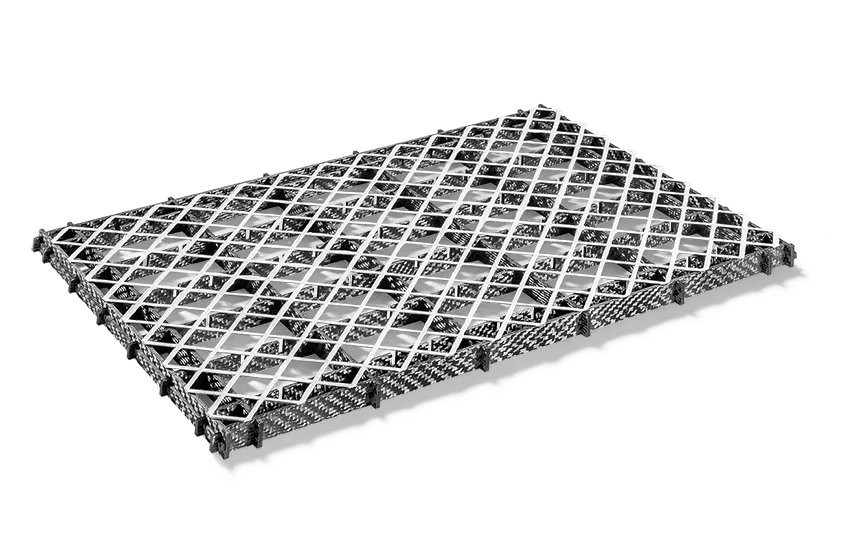

Improved energy efficiency and lower operating costs

-

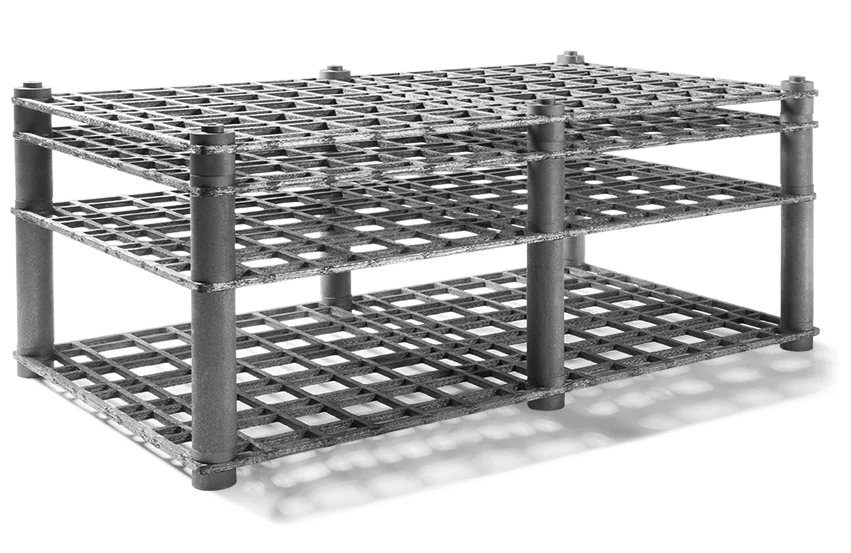

Greater productivity thanks to increased furnace load and shorter cycle times

-

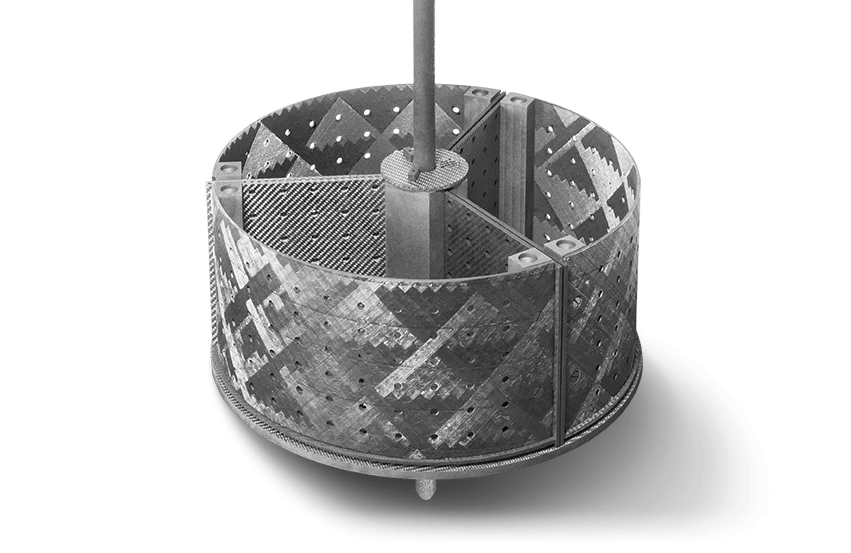

More consistent hardening results across the load

-

Option for automatic loading and unloading

-

Reduced weight and lower thermal mass

-

Long service life and minimal maintenance

Brochure: Heat Treatment

Innovative Solutions for Thermal Applications

Add

Brochure: Durafox®

Heat treatment with high-level know-how

Add

Flyer: Hybrid Fixture for Turbine Blades

Schunk Carbon Technology LLC

Add

Flyer: Hybrid Fixture for Brazing

Schunk Carbon Technology LLC

Add

Brochure: Durafire® Dense

The solution for oil quenching

Add

Downloads

5 Files online