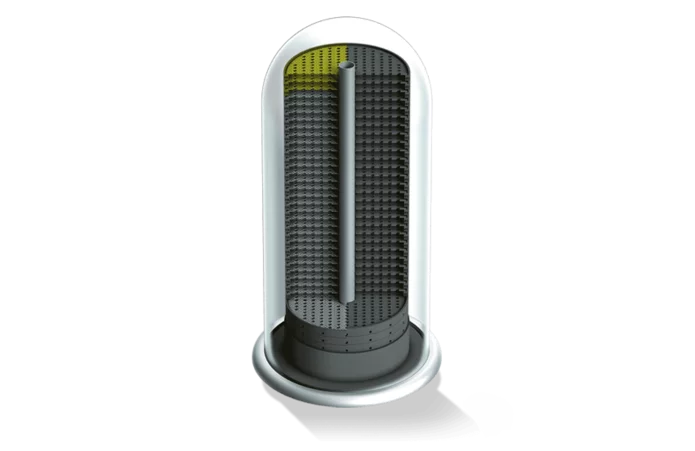

✔ Greater efficiency – Optimized materials and designs boost the output of your sintering processes

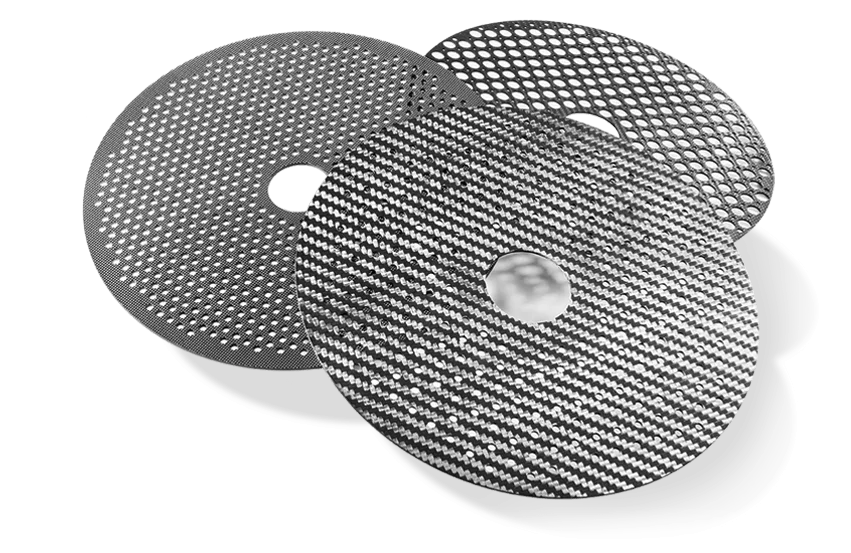

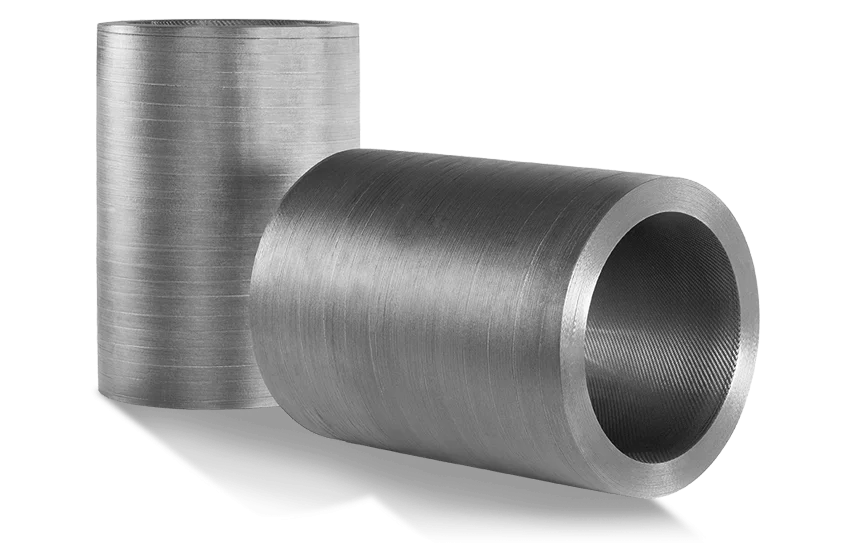

✔ Longer service life – CFC components offer excellent heat resistance and dimensional stability

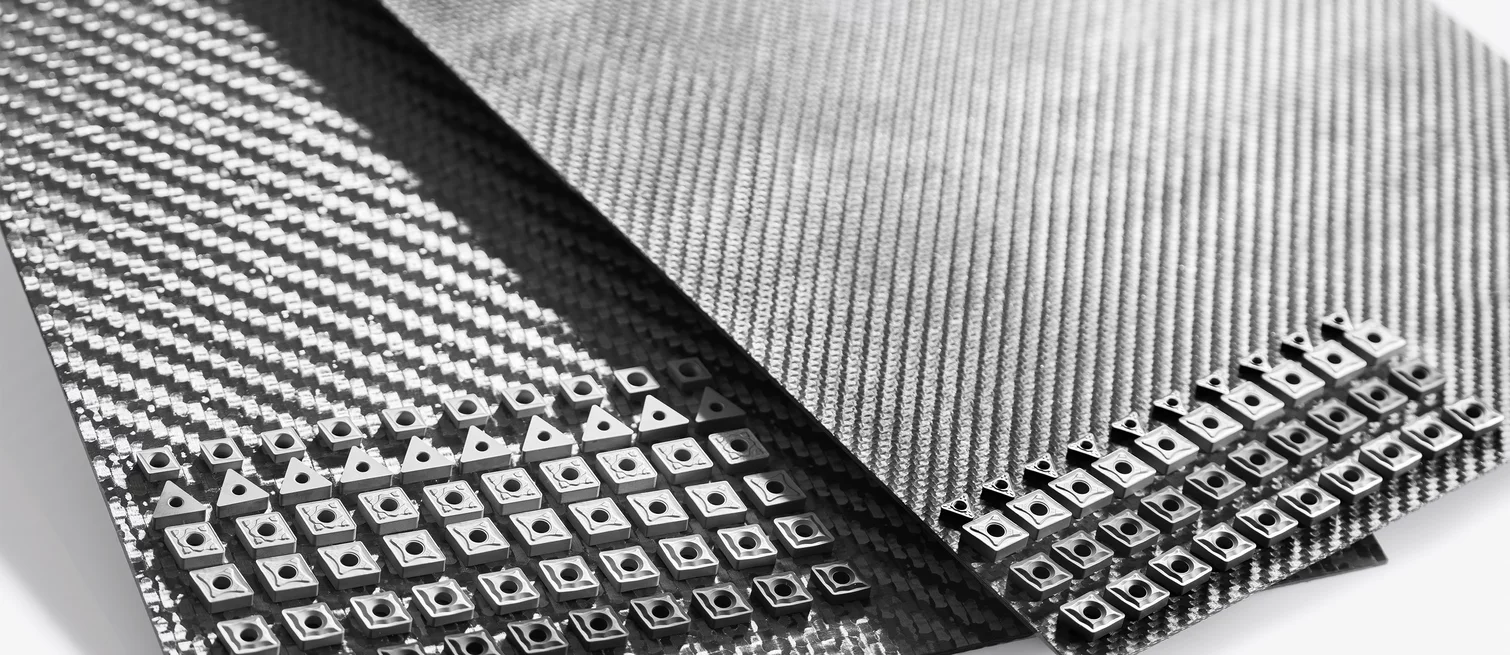

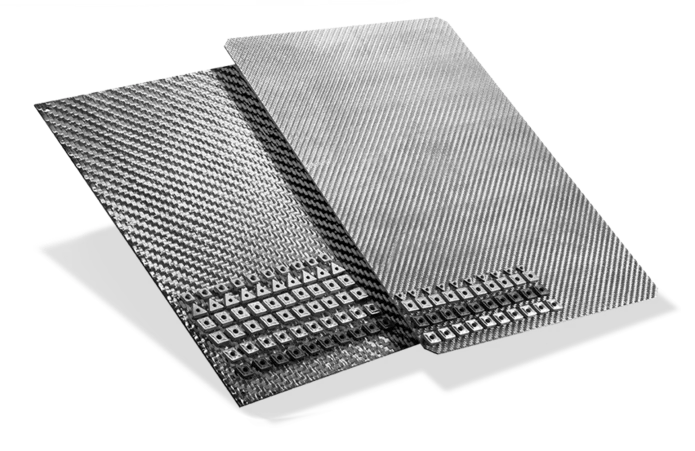

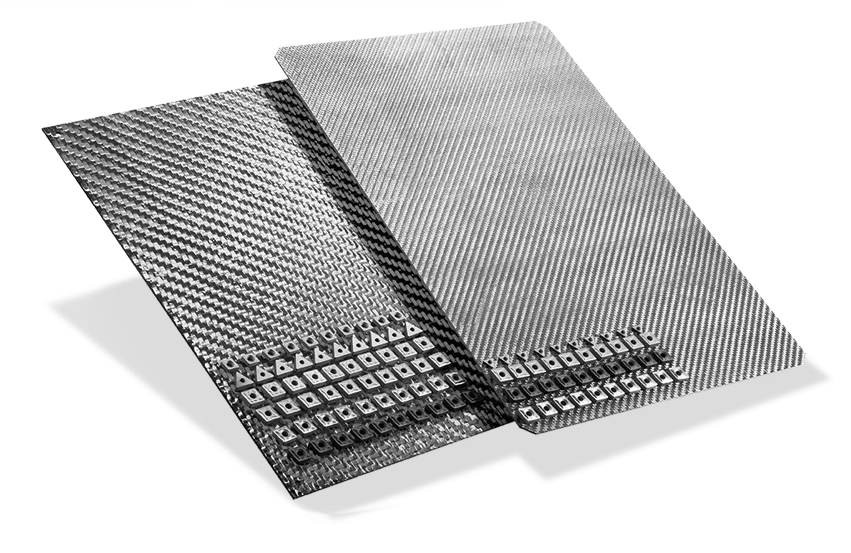

✔ Cost savings – Strippable CVD carrier plates enable multiple reuse cycles

✔ Maximum stability – High-performance CFC for precise, load-bearing fixtures and support rings

✔ Lower energy consumption – Lightweight, thermally efficient materials reduce operating costs

✔ Customized solutions – Tailored components with FEM-optimized designs

✔ Full-service approach – Engineering, development, production, and spares – all from a single source

Take advantage of our high-temperature expertise to secure your competitive edge.