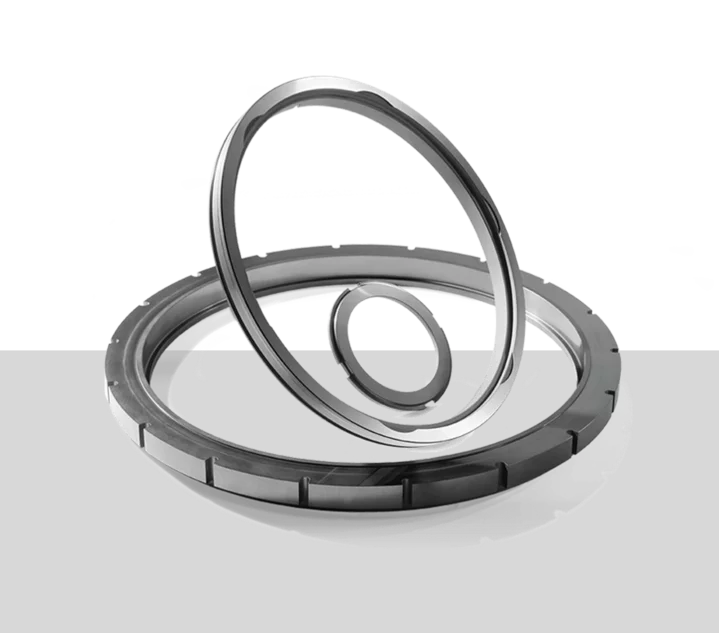

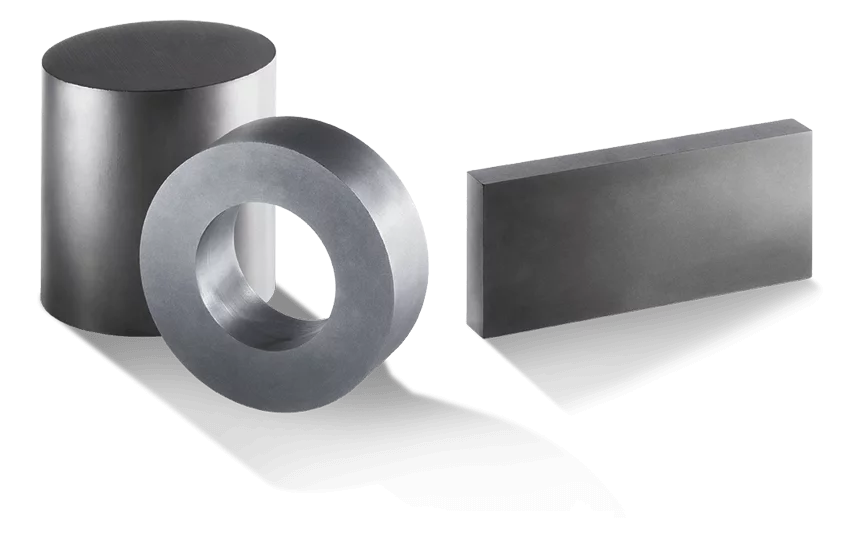

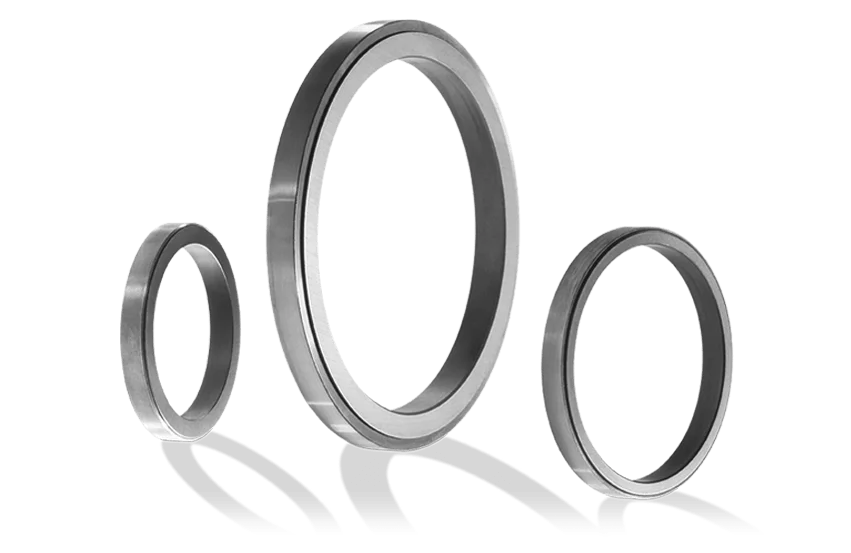

Brochure: Sealrings and Bearings made of SiSiC and SSiC

Reliable under the Toughest Conditions

Add

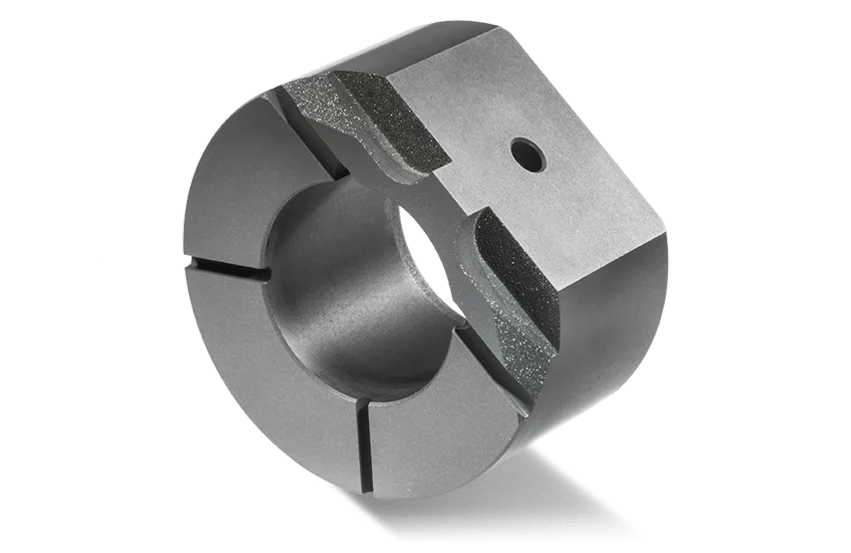

Whitepaper: PrimeCarb®

Reliable sealing operation in the most critical applications

Add

Brochure: Chemical Resistance

Chemical Resistance - Carbon Based Materials

Add

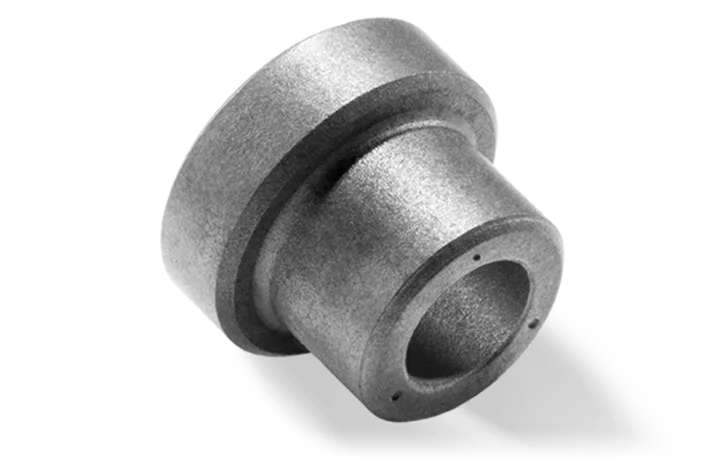

Brochure: SiC30

SiC30 – An Extraordinary Silicon

Carbide/Graphite Composite Material

Add

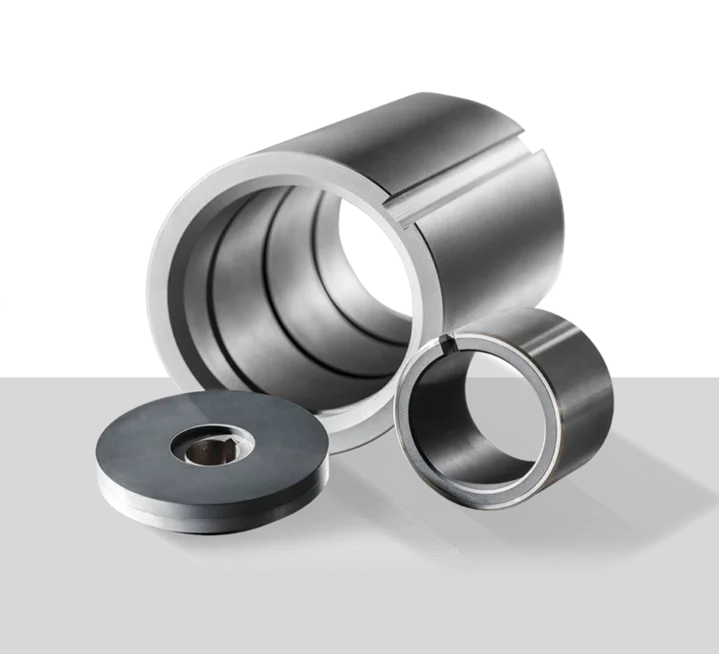

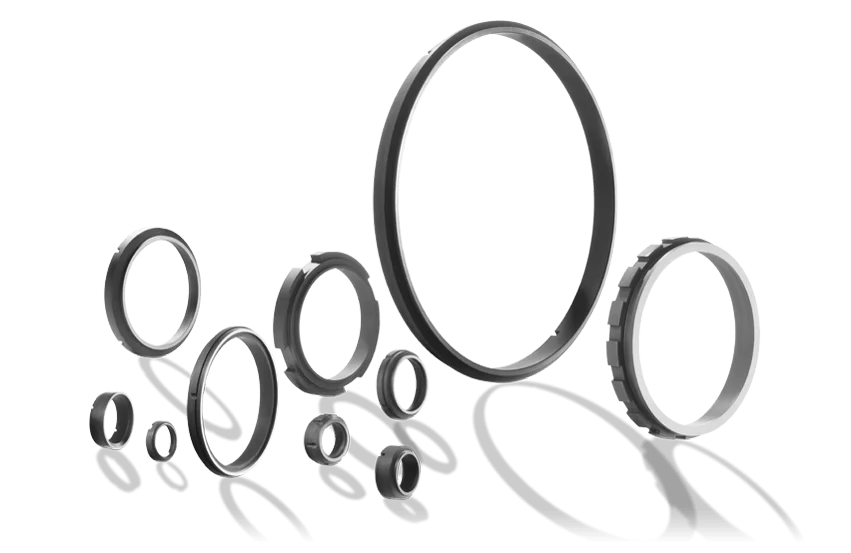

Brochure: Rings for Dynamic Seals

Carbon Materials in Dynamic Seals

Add

Brochure: Wind Energy

Innovative Carbon Solutions for Onshore and Offshore Use

Add

Brochure: Current Transmission

Schunk Industry - Your Partner in Industrial Power & Signal Transmission

Add

Downloads

7 Files online