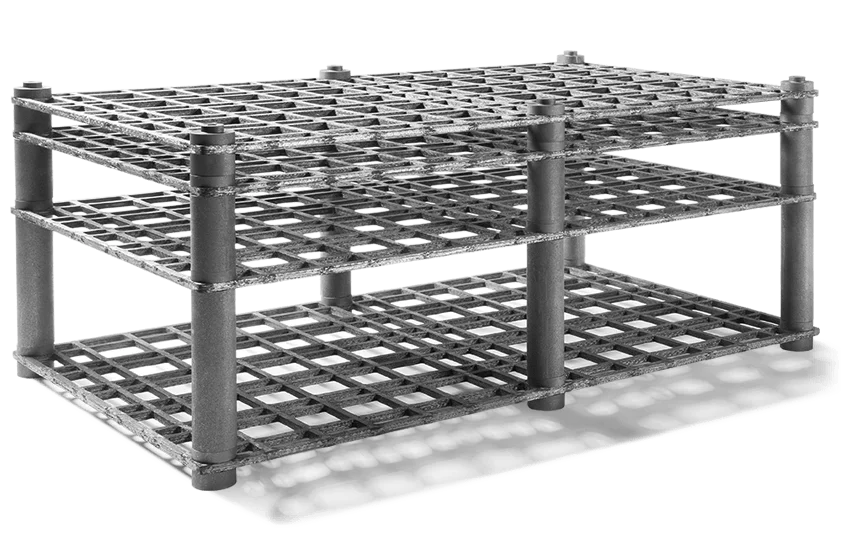

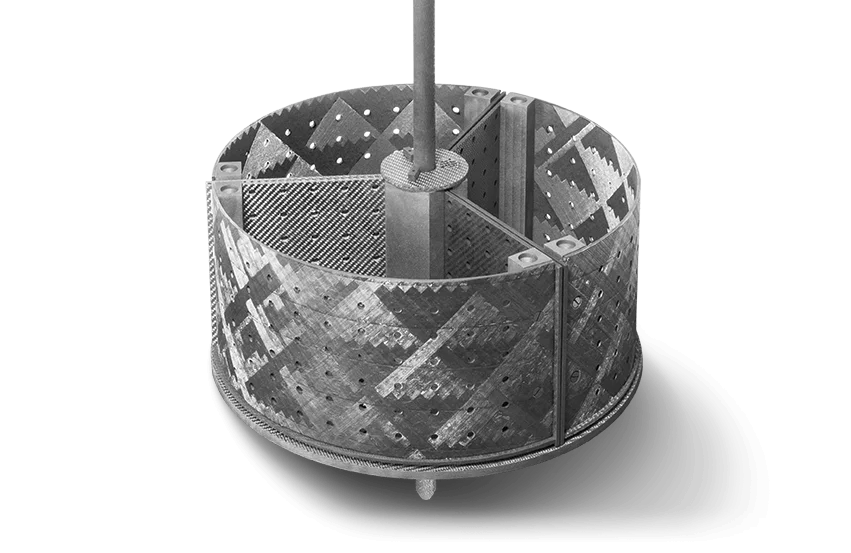

CFC Fixtures – Innovative Charging Systems for Optimal Heat Distribution

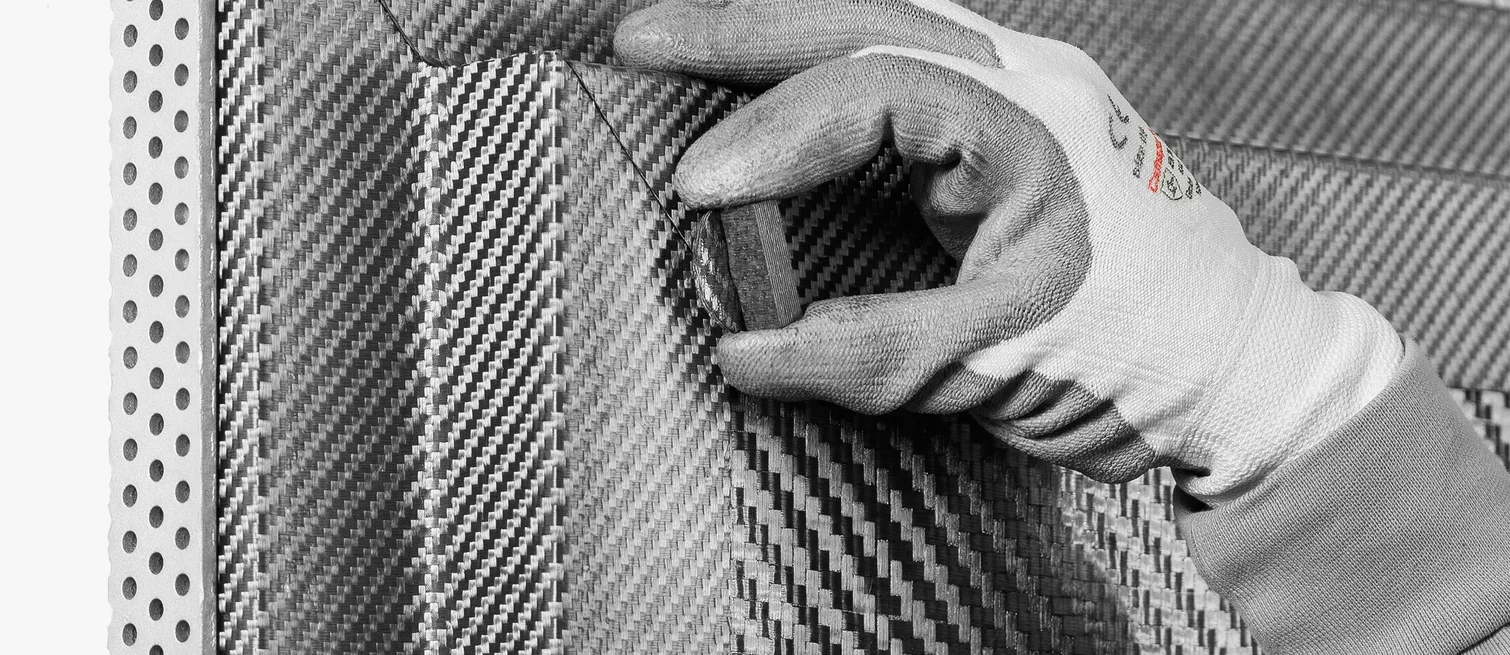

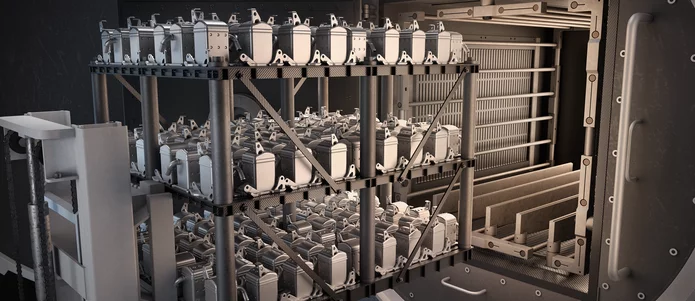

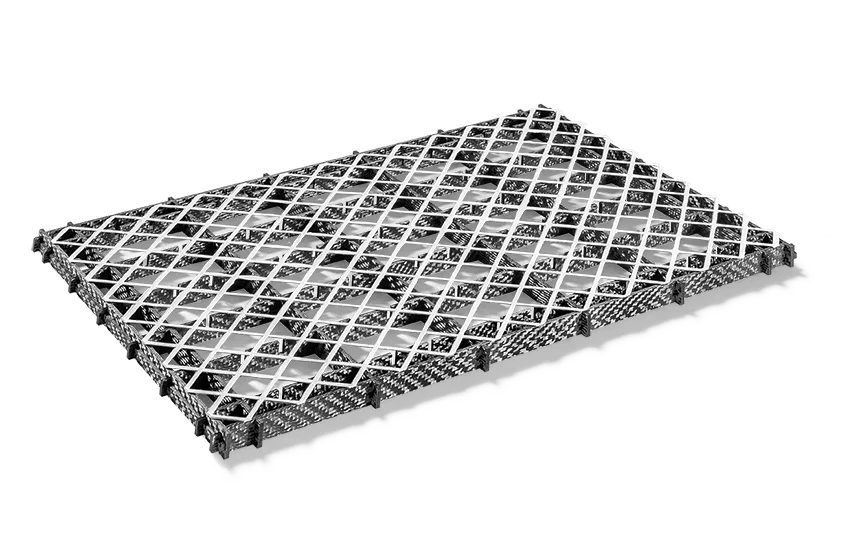

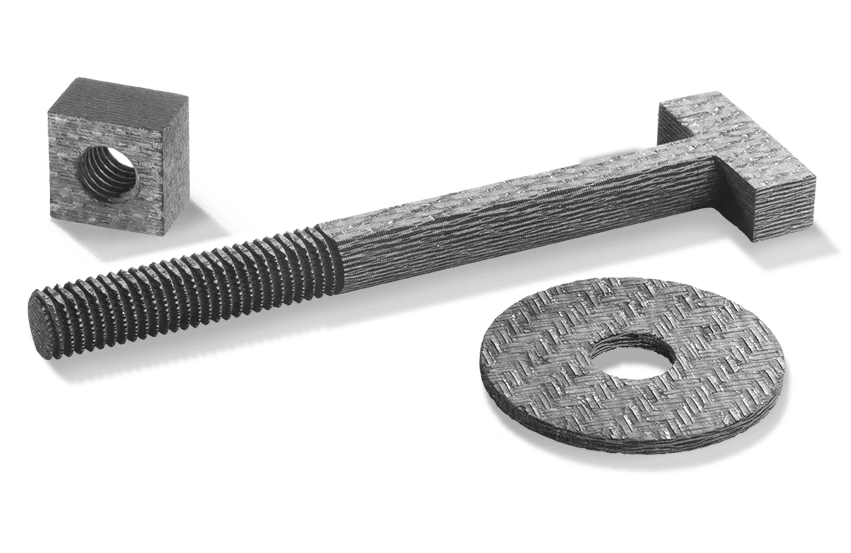

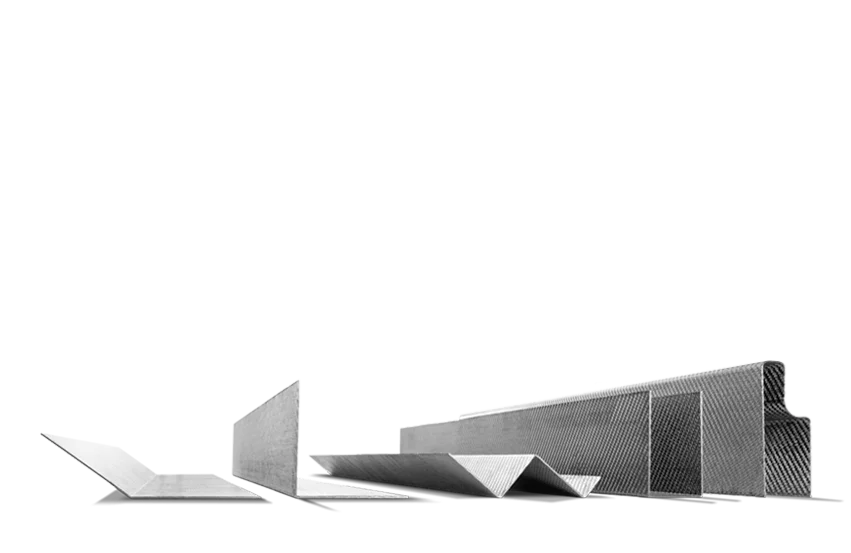

The right choice of fixtures is critical for heat treatment efficiency. Traditional cast grids come with significant drawbacks: they are heavy, prone to deformation at high temperatures, and prolong cycle times. Our CFC fixtures made from carbon fiber-reinforced carbon (CFC) are a superior alternative. Their low weight, excellent thermal resistance, and robust construction enable faster loading and unloading of parts. This reduces process times, energy consumption, and the risk of distortion. We also offer tailored fixture systems, barrier components, and our modular UniGrid® system – providing flexible solutions for a wide range of heat treatment applications.